About US

Tuobituo is a 13-year of experience as kitchen knife manufacturer. Specialized in making Damascus steel knives with the largest market share in USA market steel knife. We exchange knowledge with Japanese & Europe knife makers constantly and do joint research with Wuhan University in order to find more economical but higher-performance steel. We also provide the distributorship services in the field stainless steel.

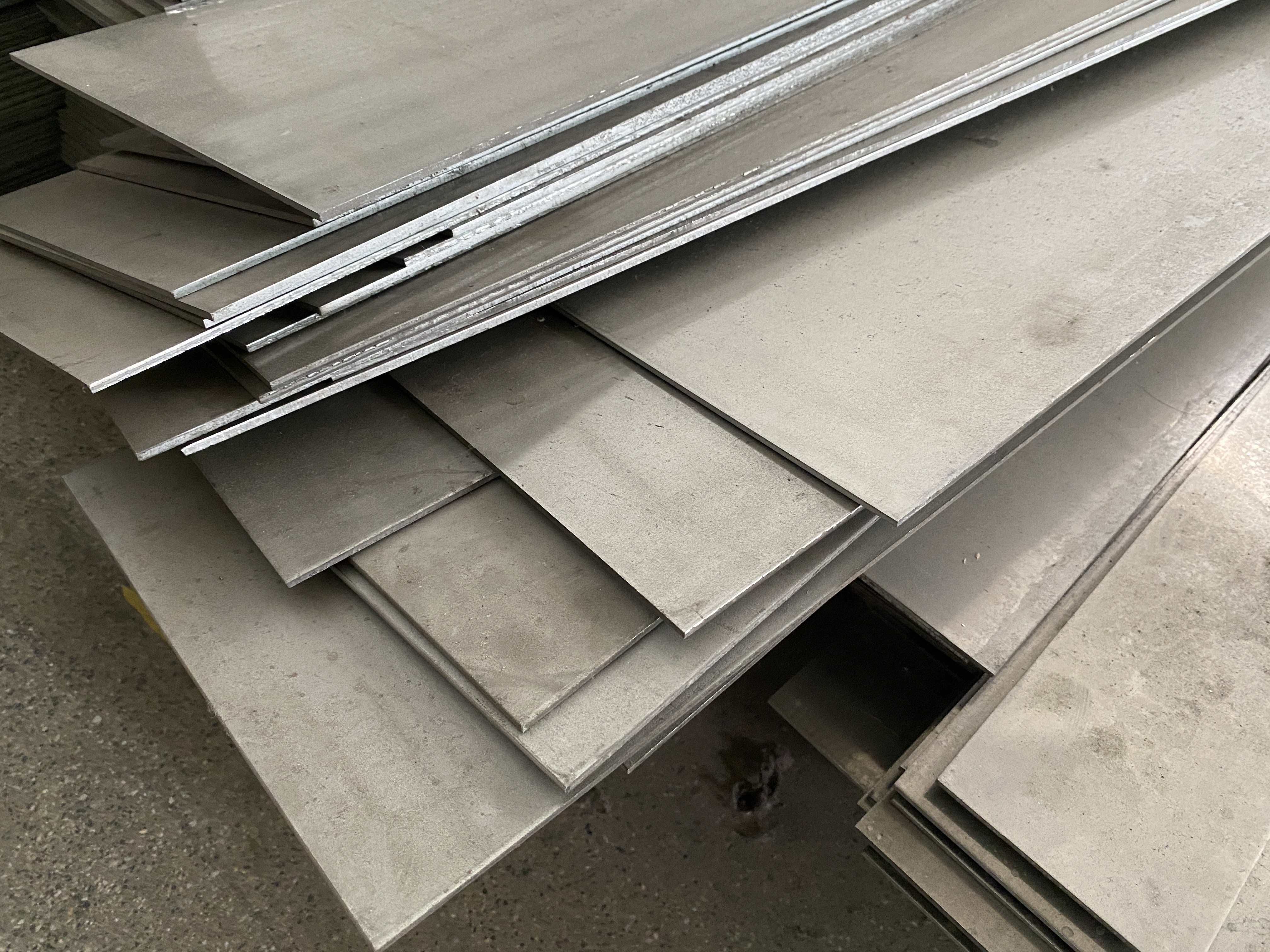

Introduction of our steel service

We specialized in distributorship services in the field stainless steel sheets,the advertising planning and market analysis in steel trading business

We can also provide the customers with the services as follow:

Custom steel rolling and fabrication to the order and specification of others; Cutting and processing of materials; Heat treatment of metals.

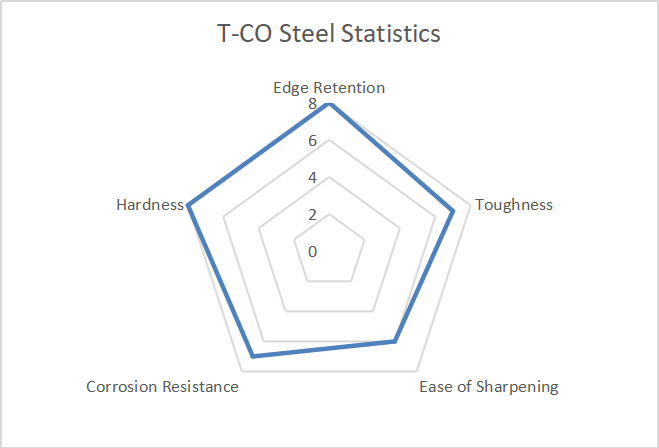

T-CO steel Introduction

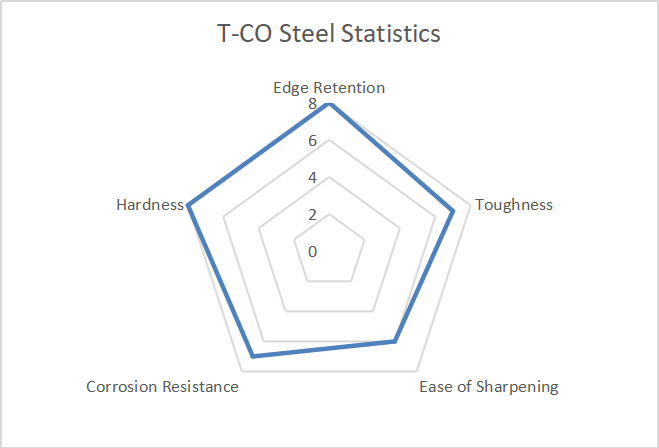

T-CO steel is a high-performance stainless steel containing cobalt. It was specially developed to compete or even outperform VG10. It has similar chemical composition to the VG10.Compared with VG10,T-CO steel is composed of carbon (1.20 % against 1.05%), chromium (18.0% against 15.5%), molybdenum (1.5% against 1.20%) and cobalt (1.80 % against 1.37 %). The addition of 18% of chromium, 1.5% of molybdenum and 1.8% of cobalt makes the matrix of T-CO stronger and prevents carbides from dropping out.The combination of chromium, molybdenum and vanadium forms a lot of hard carbides, so that the abrasion resistance improves which gives knives long-term clean cutting. By combining higher carbon and vanadium, T-CO has better performance in terms of hardness and wear resistance, edge sharpness and durability.By using higher cobalt,T-CO has been increased strength and hardness, and permits quenching in higher temperatures. Besides,it has been increased resistance to heat and corrosion by adding cobalt..T-CO steel has been tempered to a hardness of around 61 HRC.

T-CO Steel Composition Analysis

|

C |

Cr |

Mo |

V |

Co |

Mn |

P |

Ni |

Si |

| T-CO |

0.95-1.20 |

17.00-18.00 |

1.00-1.50 |

0.1-0.25 |

1.70-1.90(average 1.80) |

0-1.00 |

0.04 |

0.11 |

0-1.00 |

Application and advantage of T-CO 69 Damascus steel

T-CO 69 Damascus steel is made of high quality 69-layers of steel. The steel core is T-CO and the chemical composition is closed to VG10. The interior core steel is painstakingly sandwiched between 68 layers. The layers are well combined with the clear lines.

U-CO 69 Damascus steel is another astonishingly-looking and high-performing steel. It can produce multi-purpose kitchen knives. With its 69-layers of Damascus pattern, it will be the star of your kitchen.The knife with T-CO 69 Damascus steel is a superb, versatile kitchen knife with a great balance, incredible sharpness, resistance to rust. With its beautiful 69-layers Damascus pattern,you will wonder how they even make these patterns!

Thermal Treatments

Heating

The heat treatment process of the T-CO 69 Damascus steel is that heating at 1075 ℃ for 30 minutes.

Quenching

Put steel into the water-cooled oil furnace with oil cooling at 36℃ for 3 minutes. When the temperature drops to about 60°C, put the steel into oil removal equipment and flatten steel.

Secondary Heating

When the furnace is heated to 250 °C to 300 °C, put the steel into the furnace for 30 minutes. Then cool in still air to room temperature.